In 2020, the country was challenged by product shortages affecting everything from toilet paper to hand sanitiser. Now 2021 is presenting a new obstacle: a low supply of the silicon chips used in computers, smartphones, gaming consoles, and other electronics. After reading some of the coverage of these shortages, you might be concerned that, in a few months, you won’t be able to buy certain devices at all. That’s not quite the case, but the situation may require a little flexibility and patience.

What Are Semiconductor Chips?

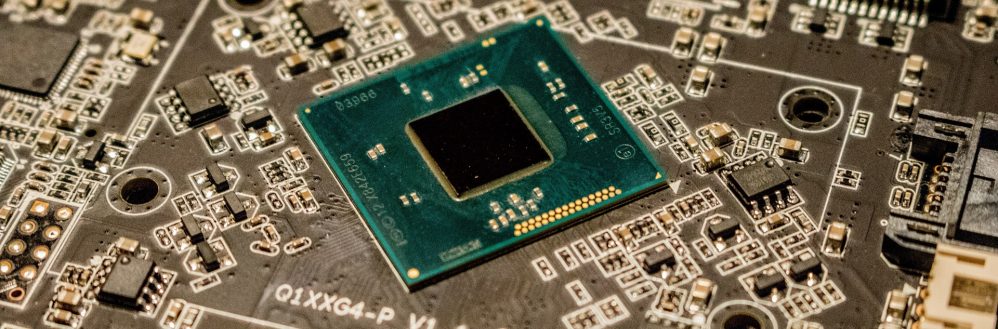

Semiconductors are materials like silicon that can conduct electricity. These are also known as chips, semis, and can be found in electronic devices such as computers, smartphones, appliances, gaming hardware and medical equipment. These devices find widespread use in almost all industries, especially in the automobile industry. Over the years, chip designers have managed to squeeze more and more circuits into smaller spaces, making computers exponentially faster and cheaper. But the tiny size and complex design laid the groundwork for the current shortage.

What is causing the global chip shortages?

This shortage has been triggered by a dramatic spike in demand, caused by the pandemic. Having declined between 2018 and 2019, global semiconductor sales revenue grew 6.5% in 2020, to $439bn, according to figures from the World Semiconductor Trade Statistics organisation. It is predicted to grow again in 2021, to $469bn. Given the huge numbers involved, this increase has inevitably put supply chains under pressure. The spike in demand is exacerbated by the industry’s reliance on a small group of foundries, particularly Taiwan’s TSMC and South Korea-based Samsung.

The increased demand follows the growing use of digital technology under lockdown. Demand for PCs rose as companies around the world pivoted to remote working and schools switched to online learning in the wake of the Covid-19 pandemic, while the growth of cloud services meant a higher number of server chips was also required. “The pandemic shifted electronics demand to consumer electronics and hyper-scale servers, and 5G came around the corner at the same time,” explains Gaurav Gupta, vice-president for semiconductors and electronics at Gartner.

The reason why carmakers are especially challenged is that cars sales plummeted during the lockdown, meaning manufacturers cut their usual semiconductor orders. As a result, Gupta says automotive companies are being deprioritised by over-stretched chip foundries as demand for their products picks up. “Industrial and auto sector demand went down and they cut down their chip orders,” he explains. “Now they can’t get back in the queue. The foundries business model is based on profit margin and volume; automotive electronics is a very small fraction [of their business], so now when the demand has picked up and the automotive guys need chips they are not seen as a priority.”

Tensions between the US and China have also played a role in the shortage, Gupta says. “The trade war led to Huawei and its competitors piling up inventory in Q2 and Q3 of 2020 leading to high foundry utilisation,” he says. “Additionally, sanctions on [Chinese chip foundry] SMIC led their customers to look for alternative options, further stressing foundry capacity in Taiwan.”

Is the Chip Shortage Benefitting Electronic Industries?

With the demand of consumer electronics rising Neil Campling, an analyst at Mirabaud Securities told The Guardian,“this gives companies the power to raise prices and pass on higher costs”. Lenovo Group also said that its profit margins took a hit after the global chip shortage. Demand for laptops has increased because of purchases by people working at home, which has also led to the doubling of stock prices since August.

When Will The Shortage be Resolved?

US President Joe Biden has intervened to resolve this issue and has sought $37 billion in funding for legislation to supercharge chip manufacturing in the country. Meanwhile, semiconductor industries have also ramped up their production process but have warned that the increase won’t be rampant. Intel has recently announced to invest $20 billion in two new factories in Arizona. However, this does not mean that the factories can meet the current demand, experts say that the scarcity will last for more than a year from now at least.

How does this affect your business?

If the global chip shortage continues to increase, this means that you won’t be able to buy popular products such as laptops, iPhone devices, PlayStation consoles and cars too. Recently, Samsung decided to shut down its factories amid the global crisis. This could mean that prices of tech gadgets could go even higher and will be heavy on your pockets.

This will affect small and medium-sized businesses (SMBs) in many ways, especially—but not exclusively—when it comes to IT. (For example, if the business or organization exists in a manufacturing vertical dealing with electronics, IT may not be the primary concern!) Boiled down, lower supply equals higher demand. Higher demand equals higher costs. Companies may have to look outside their normal standards to find similar products for workstations or peripherals, for example. Hardware orders may take (sometimes significantly) longer to be fulfilled by vendors, and IT projects may be delayed. This highlights a need for proper planning and perhaps some additional padding in IT budgets specific to integration projects. A company’s decision-makers may need to weigh the real cost of moving forward now and paying a little more versus the opportunity cost of waiting.

As demand for Wi-Fi, Bluetooth, IoT devices, handhelds, laptops, and servers continues to grow, there appears to be no near-term solution to the semiconductor shortage and disruption to supply. Businesses looking to expand networks or update hardware may have a difficult time sourcing equipment right now. If you are planning any devices or hardware in your near-term IT budget, let’s talk about sourcing your hardware sooner rather than later.